Modern Thermal Design provides geothermal solutions as well as Hydro Turbines.

Geo-Thermal and Hydro Turbines

Ground Source Heat Pumps (GHPs) utilize a type of technology that enables the transfer of heat energy between underground reservoirs and conditioned buildings. This system has three key subsystems that work in tandem to achieve the desired results. The first is a closed heat collector loop that circulates fluid through an outdoor bore field to absorb or reject heat. The second involves heat pump units that concentrate and transfer heat into or out of the ground reservoir. The third subsystem includes forced-air ducts or water pipes that directly heat or cool indoor spaces.

GHPs are particularly beneficial as they leverage the relatively constant temperatures of underground reservoirs throughout the year to provide energy-efficient and eco-friendly heating and cooling. By utilizing this natural resource, GHPs significantly reduce energy consumption, providing considerable cost savings and carbon emissions reduction.

In summary, GHP systems are a highly efficient and effective way of heating and cooling buildings. With their subsystems working in synergy, they provide a reliable and eco-friendly alternative to traditional heating and cooling systems, making them a valuable asset in both commercial and residential settings.

What our engineers look for:

- 1. Borefield sizing and design

- 2. Space constraints

- 3. Retrofitting requirements

- 4. Heat pump placement

- 5. Backup or hybrid options

- 6. Heat pump make and performance

- 7. Drilling costs

- 8. Upfront expense and payback period. ROI and Tax Incentives

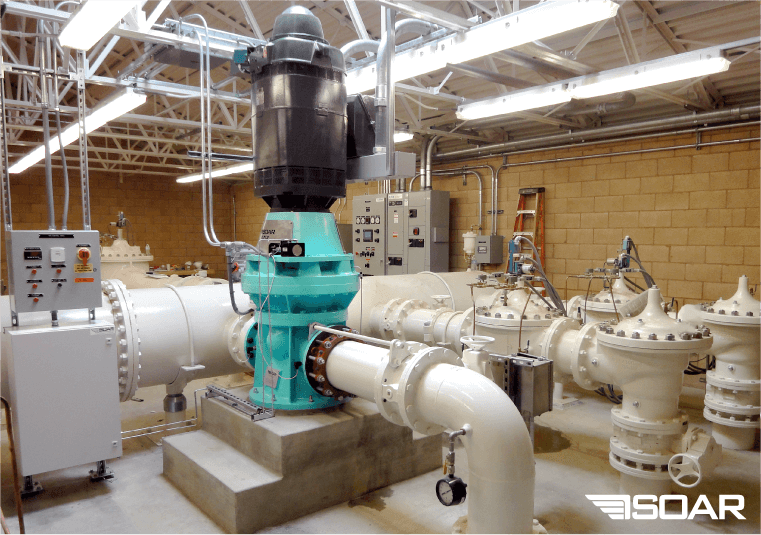

Hydro Turbines

MTDs products of choice are provided by SOAR Hydropower. We provide a complete package including stamped drawings, expert third-party information on tax incentives, and ROI analysis.

In-Line Hydro Turbine

In-Line Series (ILT)

6″-24″ Pipe Sizes

50-570 Feet Head

500-30,000 GPM Flow Rates

SOAR Hydropower’s in-line turbines (ILTs) include a series of compact and highly efficient hydropower generation units designed to be site-specific for maximum efficiency. These turbines are ideal for conduit power recovery and available in standard pipe sizes ranging from 6 to 24 inches. The ILTs share many common parts that contribute to their competitive pricing and short lead times. It is noteworthy to mention that SOAR’S US Patented ILTs are American-made and assembled in the USA. These turbines are meticulously designed and constructed to ensure reliability, durability, and optimal performance.

SOAR Hydropower’s in-line turbines are a reliable and efficient option for hydropower generation, featuring site-specific design, competitive pricing, and short lead times. With their common parts and compact design, these turbines are a smart choice for maximizing efficiency and minimizing costs.